A Real-Time Computer Vision-Based System for Detecting Defects in Injection-Molded Products

DOI:

https://doi.org/10.70844/ijas.2024.1.10Keywords:

Injection molding, Computer vision, Defect detection, Automated system, Preprocessing techniquesAbstract

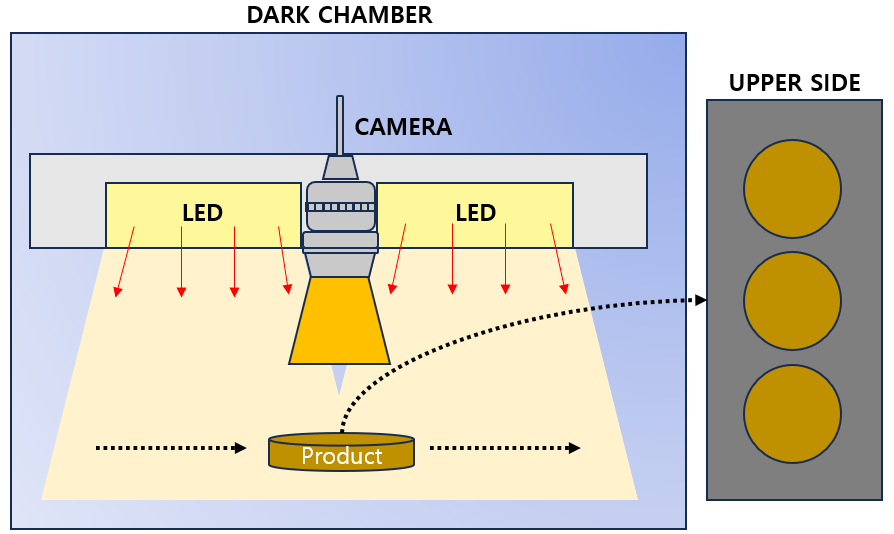

This study proposes an automated system for detecting and classifying defects in products manufactured through the injection molding process. Existing deep learning-based detection technologies provide high accuracy, but have limitations in that they require massive data and complex learning processes, and require re-learning when new products are introduced. On the other hand, simple image processing techniques can be applied quickly without a learning process, but there are limits to accuracy when defect types are complex or diverse. To solve this problem, this study introduced advanced computer vision technology to overcome the limitations of existing technology and designed a system that excludes the complexity of deep learning. In particular, this system combines various pre-processing and post-processing techniques such as grayscale conversion, binarization, Gaussian filtering, and histogram smoothing to simultaneously improve the accuracy and efficiency of defect detection. In addition, it was designed to quickly detect defects occurring in the manufacturing process through a system architecture that optimizes real-time processing. Using ultrasonic sensors and automated conveyor belts, the product movement and detection process is precisely controlled, enabling real-time data processing and product classification. As a result of the experiment, this system significantly reduced detection delays and classification errors that commonly occurred in existing research, and demonstrated its potential to contribute to quality control and productivity improvement in a manufacturing environment.